zanen tabarau

Gabaɗayan firam ɗin gilashin ido yana buƙatar ƙira kafin a fara samarwa. Gilashin ba samfurin masana'antu ba ne sosai. A haƙiƙa, sun fi kamance da na'urar hannu ta keɓantacce sannan kuma aka yi ta da yawa. Tun ina karama na ji kamar kamannin gilashin bai kai haka ba, kuma ban taba ganin wanda ya saka su ba. Ee, shagon gani shima yana da ban mamaki…

Mataki na farko na fara ƙirar masana'antu ~ Mai zane yana buƙatar zana ra'ayoyi uku na gilashin farko, kuma yanzu yana kan kai tsaye a kan ƙirar 3D, da kuma kayan haɗi da ake buƙata, irin su gilashin gilashi, temples, santsi na hanci, hinges. , da dai sauransu Lokacin zayyana, siffar da girman kayan haɗi suna da matukar bukata, in ba haka ba za a shafi daidaiton taro na sassan da ke gaba.

da'irar tabarau

Samar da firam ɗin gilashin ido a hukumance yana farawa da babban nadi na waya na ƙarfe a hoton da ke ƙasa ~

Na farko, saitin rollers da yawa suna mirgine waya yayin fitar da ita kuma a aika don yin zoben gilashin ido.

Mafi ban sha'awa na yin da'irar tabarau ana yin ta injin da'irar atomatik wanda aka nuna a hoton da ke ƙasa. Dangane da siffar zanen sarrafawa, yi da'irar sannan a yanke shi. Wannan kuma yana iya zama mataki mafi sarrafa kansa a masana'antar gilashi ~

Idan kuna son yin gilashin rabin firam, zaku iya yanke su cikin rabin da'irar ~

Haɗa zoben madubi

Za a saka ruwan tabarau a cikin rami na ciki na zoben gilashin ido, don haka ana amfani da ƙaramin kulle don haɗa ƙarshen zoben ruwan tabarau.

Da farko sai a gyara sannan a danne block din, sannan a dora zoben madubi a samansa, bayan an shafa ruwan, sai a dumama waya a hada su wuri daya (ah, wannan sananniyar walda)… wanda karafa biyun da za a haxa suna cike da karfe (brazing filler metal) ana kiransa brazing~

Bayan walda biyun iyakar, za a iya kulle zoben madubi ~

gilashin gada

Sai babban bugu da abin al'ajabi… The Punch ya lankwasa gadar…

Gyara zoben madubi da gadar hanci tare a cikin mold da kulle.

Sa'an nan kuma ku bi tsarin da aka yi a baya kuma ku haɗa su gaba ɗaya ~

atomatik waldi

Tabbas, akwai kuma injin walda ta atomatik ~ Na yi saurin gudu biyu a hoton da ke ƙasa, kuma haka yake. Na farko, gyara kowane bangare a matsayin da ya kamata su kasance… sannan ku kulle shi!

Dubi wani kusa: Wannan kan walda mai soso da aka lulluɓe shi ne shugaban walda na injin walda ta atomatik, wanda zai iya maye gurbin aikin walda da hannu. Bakin hancin da ke gefen hancin, da sauran na'urorin haɗi, suma ana walda su ta wannan hanya.

yi kafafun tabarau

Bayan kammala ɓangaren gilashin gilashin a kan hanci, muna kuma buƙatar yin haikalin da ke rataye a kan kunnuwa ~ Mataki na farko shine shirya albarkatun kasa, da farko yanke wayar karfe a cikin girman da ya dace.

Sa'an nan kuma ta hanyar wani extruder, daya ƙarshen karfe yana buga a cikin mutu.

Kamar wannan, ƙarshen haikalin yana matse shi cikin ƙaramin kumbura.

Sannan a yi amfani da karamar inji mai naushi don danna karamar buhun ganga mai laushi da santsi ~ Ban sami hoto mai motsi kusa da nan ba. Bari mu kalli hoton tsaye don fahimta… (Na yi imani za ku iya)

Bayan haka, za a iya welded hinge a kan ɗakin kwana na haikalin, wanda za a haɗa shi da zoben gilashin daga baya. Lalacewar haikalin ya dogara da daidaitaccen daidaituwar wannan hinge ~

Haɗa sukurori

Yanzu yi amfani da sukurori don yin haɗi tsakanin haikalin da zobe. Sukullun da aka yi amfani da su don hanyar haɗin gwiwar ƙananan ƙananan ne, game da girman Xiaomi…

Hoton da ke ƙasa shine ƙarar dunƙulewa, ga kusa-kusa ~ Yarinyar cute wanda sau da yawa yana murɗa screws don daidaita matsi da kansa dole ne ya sami zuciya…

Gyara hinges na haikalin, yi amfani da injin don murƙushe sukullun ta atomatik, da murɗa su kowane minti daya. Amfanin yin amfani da na'ura ta atomatik a yanzu ba kawai don adana aiki ba, har ma don sarrafa ƙarfin da aka saita. Ba zai yi yawa ba idan ba a ƙara shi da maki ɗaya ba, kuma ba zai yi sako-sako ba idan ba za a rage shi da maki ɗaya ba…

Nika

Firam ɗin welded kuma yana buƙatar shigar da abin nadi don niƙa, cire burrs da zagaye sasanninta.

Bayan haka, ma'aikata dole ne su sanya firam ɗin a kan keken niƙa, kuma su sanya firam ɗin ya yi haske ta hanyar goge goge.

mai tsabta electroplating

Bayan an goge firam ɗin, ba a gama ba! Dole ne a tsaftace shi, a jiƙa a cikin maganin acid don cire tabon mai da ƙazanta, sa'an nan kuma a sanya shi ta hanyar lantarki, an rufe shi da Layer na fim din anti-oxidation… Ba za a iya yarda da shi ba, wannan shine electroplating!

lankwasa temples

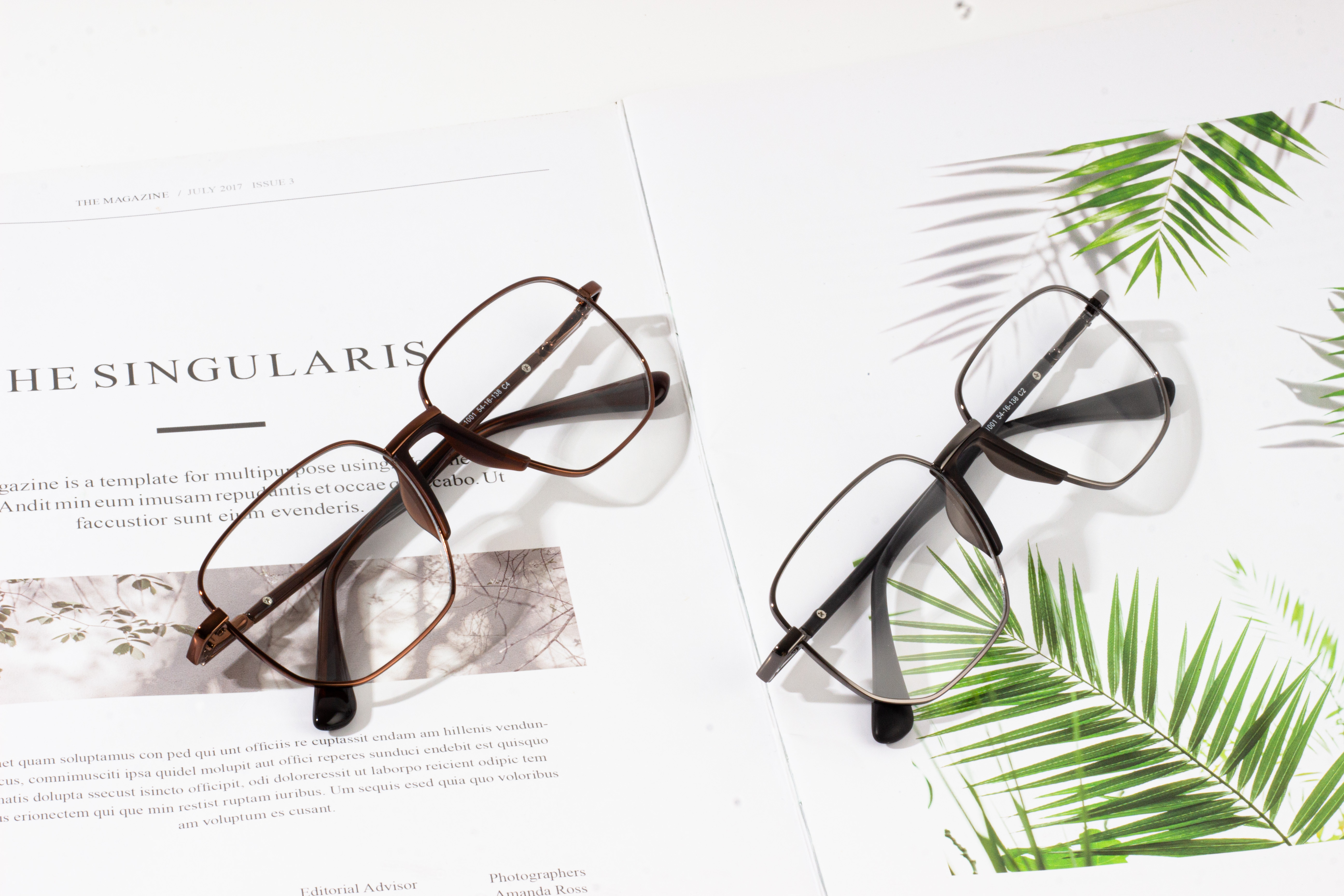

A ƙarshe, an sanya hannun rigar roba mai laushi a ƙarshen haikalin, sannan ana yin cikakkiyar lanƙwasa ta injin atomatik, kuma an kammala firam ɗin gilashin ƙarfe guda biyu ~

Lokacin aikawa: Agusta-01-2022